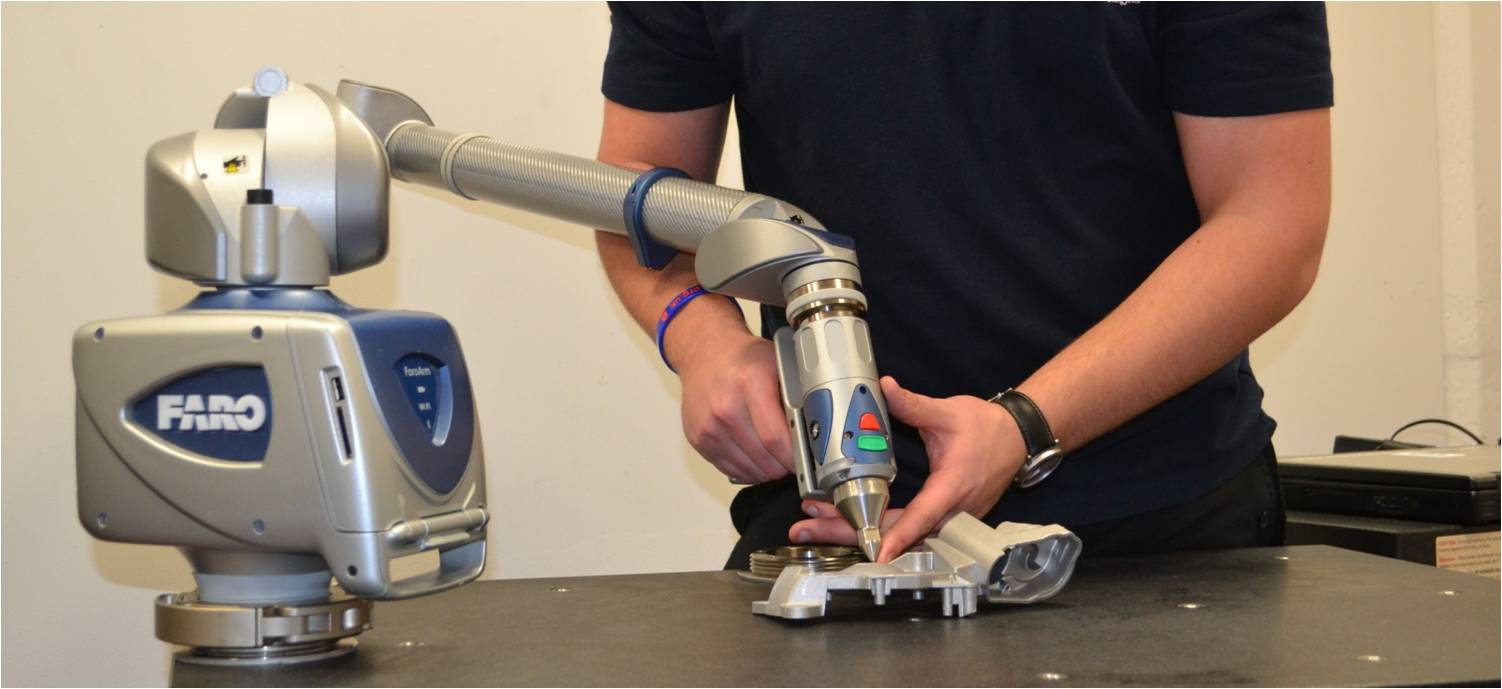

Precision Inspection and Reverse Engineering

Maximum Engineering has extensive 3D metrology experience through various projects involving new part inspection, periodic part and tool calibration, and reverse engineering. Our staff is trained and skilled in the operation of portable coordinate measuring machines including FaroArm probing and scanning, as well as the FARO laser tracker operation. We can perform precision dimensional accuracy checks in house or on-site depending on our customers’ specific needs. We provide dimensional post-processing services including reverse-engineering model generation, dimensional accuracy reporting, and more.

Reconditioning Services

Maximum Engineering also offers part rework and refinishing services to compliment our metrology capabilities. This includes re-machining of customer’s existing part surfaces to bring dimensions within specification, as well as media blasting, painting, powdercoating, or plating to an ‘as-new’ finish.