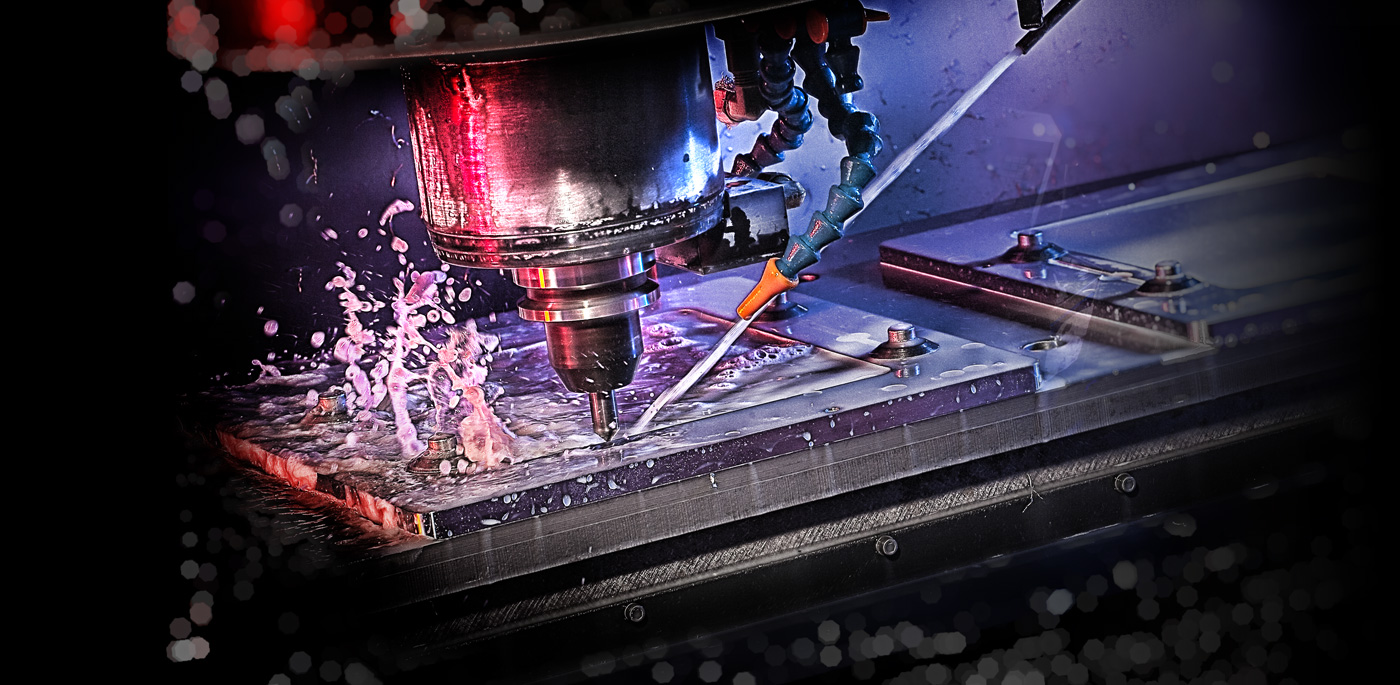

Manufacturing Services

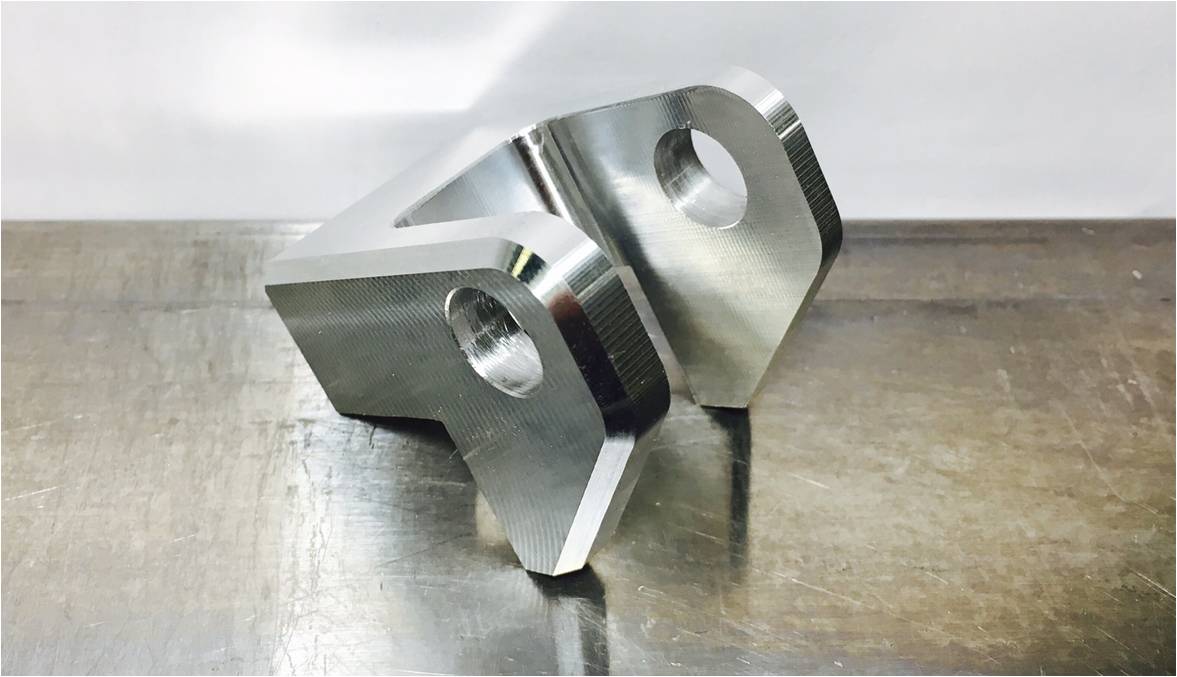

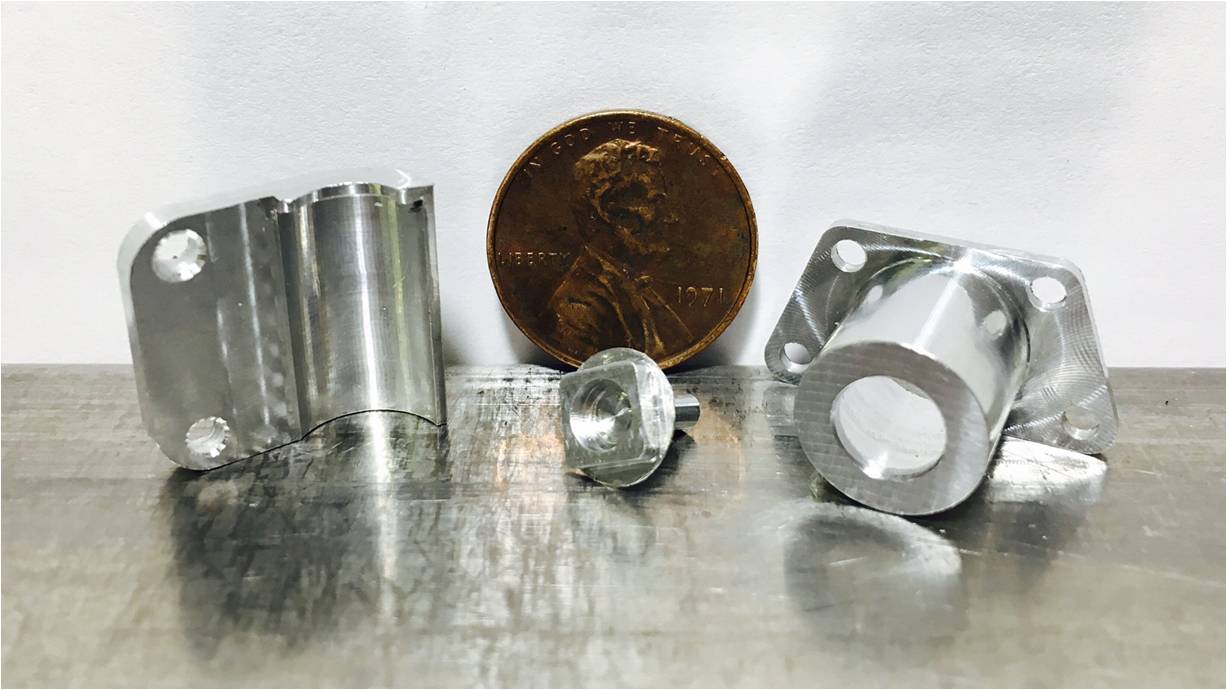

Maximum Engineering embraces the tried and true techniques of traditional machining while employing emerging advances in modern manufacturing in order to become the machine shop of tomorrow. Our 2,000 square foot facility in Chantilly, Virginia houses high precision HAAS CNC machining and turning centers to produce parts of all materials, shapes, sizes, and production volumes. We also specialize in cutting and forming, welding, fabrication, and more. Below is a list of processes and materials we are experienced with – and if you don’t see something you need, just ask.

We strongly believe in having our engineers and machining technicians in direct communication with our customers. The result is clearer translation of part requirements and suggested part design alterations, ultimately improving manufacturability, shortening lead times, and significantly lowering our customer’s costs. The team at Maximum Engineering prides itself on short lead times, and is eager to put in whatever it takes to deliver parts that meet your schedule.

Quoting

Simply submit your parts and contact information to us via email or just give us a call – we can usually provide same-day pricing!

Processes

- Milling (manual and multi-axis CNC)

- Lathing

- Plasma Cutting (manual and multi-axis CNC)

- Water-Jet Cutting

- Casting

- Injection Molding

- 3D Printing

- Laser Cutting

- Engraving

- Thermoforming

- Routing

- Heat Treatment

- Welding

- Tube bending and notching

- Surface Grinding

Standard Manufacturing Methods

- Drilling, boring, reaming, countersinking, tapping, broaching, honing

- Grinding, shearing, braking (bending)

- Media Blasting, wire brushing, polishing, buffing

- Plating, etching, coating (paint and powdercoating)

- Various cutting/sawing

Materials

- Metals

- Plastics

- Wood

- Glass